Demand Forecasting in Manufacturing: From Data, to the Future

The manufacturing industry may involve some of the most complex processes in multiple areas, from raw material management to the supply chain to resources and technology. All these areas need a precise balance, which helps manufacturers ensure better resilience in the face of unexpected market conditions and shifts. In balancing this entire ecosystem, manufacturing demand forecasting takes a central role. This allows manufacturers to predict demand, coordinate production, anticipate raw materials needs, etc.

What we'll Cover:

Manufacturing Forecasting: What Is It?

While it is difficult to predict all these moving pieces in manufacturing scenarios, manufacturers have taken a particular interest in attempting to. Manufacturing forecasting is a company’s ability to anticipate market evolutions and adapt its strategy to ensure organizational resilience. To better predict market trends and shifts, companies rely on business forecasts. These contribute to risk reduction through proper resource allocation.

Demand forecasting can be achieved through various methods, mainly a combination of data-driven analytics and professional expertise that empowers businesses to anticipate how customer demand and markets could evolve in the projection period. Different demand forecasting models and tools can also aid the process. Below, we’ll dive into some of the widely used demand forecasting methods in manufacturing.

Manufacturing Demand Forecasting: The Methods

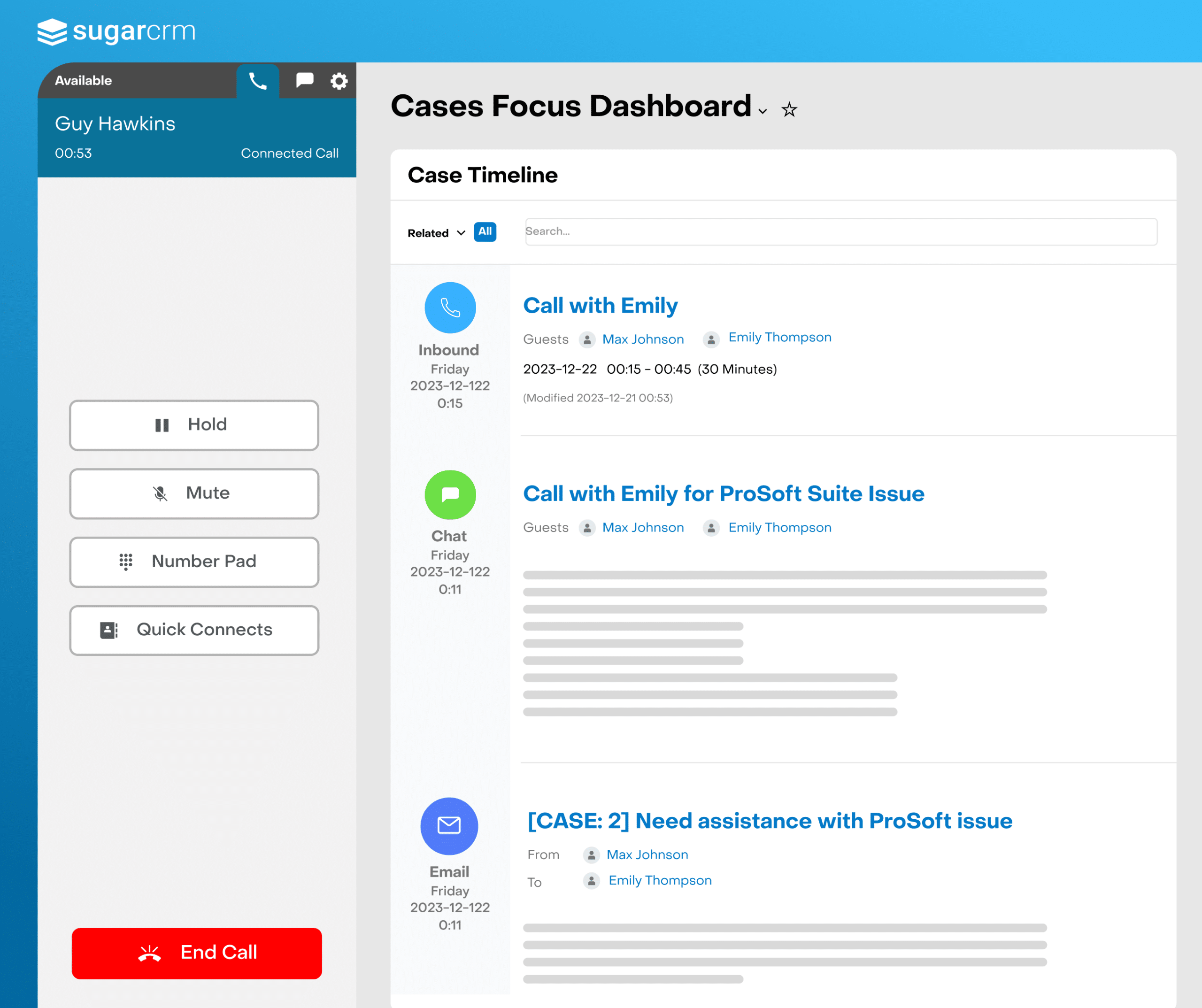

Demand forecasting is based on CRM and ERP data. After data is collected and cleaned, manufacturing enterprises must establish which demand forecasting model best suits their business and needs. Demand forecasting can be split into two categories: quantitative and qualitative forecasting:

- Quantitative Forecasting: this forecasting type uses historical data (sales history, for example) to generate predictions about future demand

- Qualitative Forecasting: this forecasting type is based on feedback and professional insights from experts and customers

Companies will use different forecasting types and methods based on their particularities. For example, companies with a long market history usually rely on quantitative forecasting since they have a long data history and generous volumes of data to work with. On the other hand, newer companies will instead rely on qualitative forecasting types to make predictions.

Sales-Driven Forecasts

Sales-driven forecasts are quantitative methods that are based on historical data. Manufacturers can look at how many units of each product in their portfolio sold in the previous years and predict demand for the following quarters or years.

This forecasting method uses solid data and information: sales volumes, customer purchase behavior, and seasonal fluctuations. For many manufacturers, this method offers more substantial data and insights.

Like all forecasting methods, this one also has its drawbacks. Customer buying patterns can change due to economic disruptions, markets can also be disrupted by the entrance of a new player, etc. But, most recently, manufacturers have started deploying generative AI and predictive analytics capabilities for forecasting purposes, especially since these technologies can combine hard CRM, ERP, and sales data with softer information like customer buying patterns, economic developments, political crisis, new competitors in the market or niche, and so forth. This allows for more dynamic forecasting that accounts for solid data and external softer shifts and changes.

Production-Driven Forecasts

Production-driven forecasts are estimations based on a manufacturing company’s production capacity. Apart from looking at the company’s production capacity, this forecasting method also factors in capabilities and historical production data. The number of manufacturing plants, employees, holidays, raw materials, everything is accounted for in this forecasting method. It also accounts for how many units of each product the company could manufacture over the previous six months.

Production-drive forecasts are very grounded in reality. This offers a series of advantages. First, each company can optimize production to allow them to only use the right number of resources. This enables manufacturers to avoid over-promising and under-delivering, like forecasting models based on market demands.

However, this prediction method also has its drawbacks. Companies can lose track of customer demands and needs without accounting for market developments and the softer information we previously mentioned. As a result, some feedback from sales and support professionals should always be incorporated into this prediction model.

Push Systems

The push system is a qualitative forecasting method using anticipated demand to estimate production. Companies that use this forecasting model leverage information about past demand and seasonal trends to determine future production. In manufacturing, this forecasting model helps companies to better manage production schedules and inventory. In return, customer demands are better met.

However, this method also has its disadvantages. Because it relies on pure predictions and estimates that aren’t backed by solid data, it can sometimes lead to excess inventory or stockouts. To overcome this limitation, companies should implement better communication standards between departments to ensure that all stakeholders’ information is accounted for.

Pull Systems

The pull method for demand forecasting is considered the most accurate. It uses the “pull” of registered orders instead of production capacity or demand estimations. In this case, companies will only start production for an item after placing an order. This way, there is no risk of overproduction. This is a reactive approach to manufacturing, not a proactive one, allowing manufacturers to avoid waste and swiftly adapt to customer needs and market demands.

However, like all methods, the pull method also has disadvantages. The most notable one is that it cannot be applied to all products. In the event of a supply chain disruption, manufacturers are also vulnerable when applying this method. To overcome these limitations, companies should look into hybrid solutions that allow them to infuse their demand forecasting approach with proactive elements.

Manufacturing Forecasting: The Challenges

As mentioned, there is no fool-proof, 100% accurate demand forecasting method. Thus, demand forecasting has several challenges that can be overcome with a healthy dose of predictive analytics, ERP, and CRM data.

- Demand volatility: it refers to unpredictable shifts in customer demands. For example, a product growing in popularity because of external factors such as social media trends will most likely generate understocking and a limited capability to meet unexpectedly high customer demand.

- Demand fragmentation: Demand fragmentation refers to consumers’ dynamic needs and preferences. It means that customers are attracted to more and more subcategories of the same product. Advanced forecasting tools with predictive analytics as part of their capabilities are a great way to overcome these limitations. Manufacturers can also base their research on frequent customer surveys for further insights into demand and preferences.

- Inaccurate historical data: Forecasting models are only as accurate as the data they handle. To overcome limitations posed by inaccurate data, you need to establish strong data management protocols and base your insights on CRM and ERP data.

- External factors: while relying on internal, complex data may be tempting, many external factors can impact demand. Economic decline, political crisis, tech breakouts, and so forth all impact a company’s ability to stick to its projections. One way to overcome this limitation is by adopting newer technologies, such as predictive analytics, that account for both internal data and external factors when predicting demand.

- Deficient supply chain visibility: Manufacturing enterprises depend on a complex ecosystem to accurately predict the future. Any disruption across the supply chain can negatively impact a company’s ability to follow projections and meet demand.

- Forecasting bias and errors: All forecasting methods are prone to errors and bias. The best way to overcome bias and errors is to rely more on CRM and ERP data and less on educated guesses.

Advanced analytics solutions and tech advancements like predictive analytics to accurately predict demand and prepare for it have become the golden standard in demand forecasting for manufacturing enterprises. ERP and CRM integrations are also a great way to leverage technology to better plan and coordinate production. If you’re interested in learning more about demand forecasting and how technology can help you overcome some of the most common bottlenecks encountered by manufacturers today, watch our Data Mastery Best Practices: How to Win Sales with Analytics webinar or read our CRM + ERP: Connecting Back-Office and Front-Office Operations infographic.